MES Basic Module – the Future-Proof Foundation

The Most Important Functions at a Glance

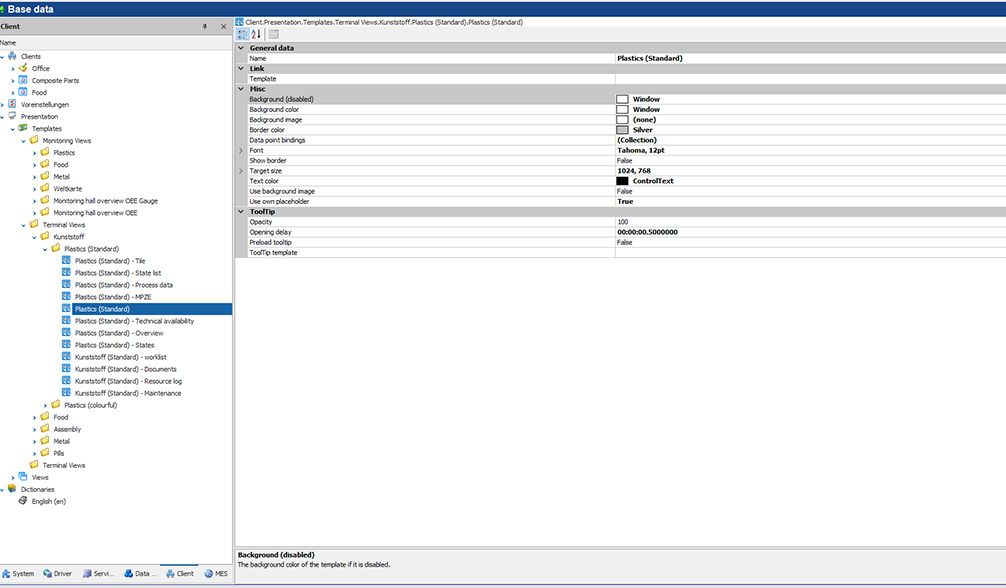

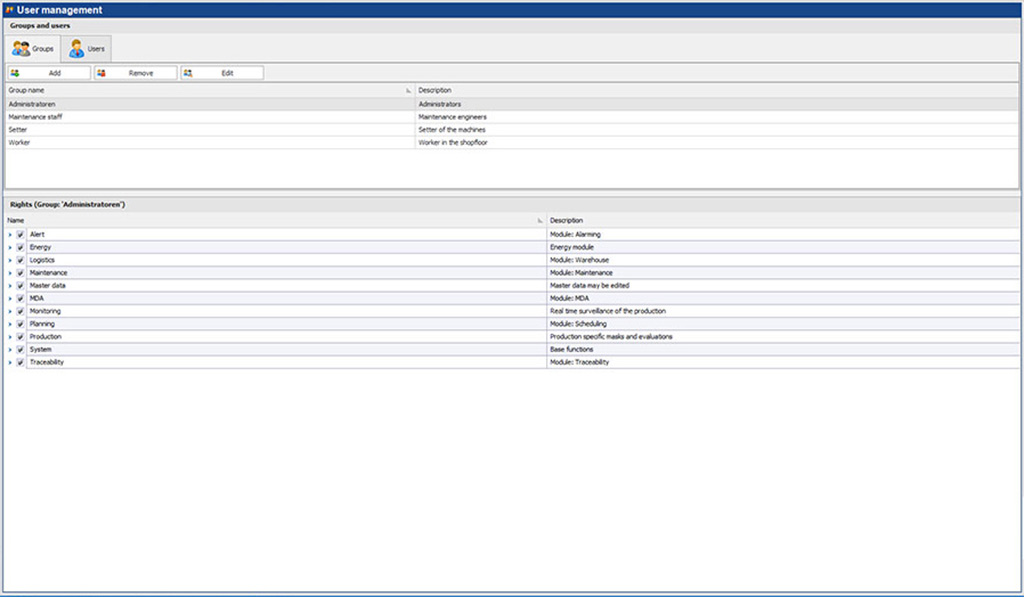

- User administration including rights management on a functional level

- Master data management of resources (e.g. machines, equipment, personnel, articles, work schedules)

- Logging of all manually made data changes and activities (audit trail)

- Printing and export functions, e.g. to Excel, sending e-mails automatically

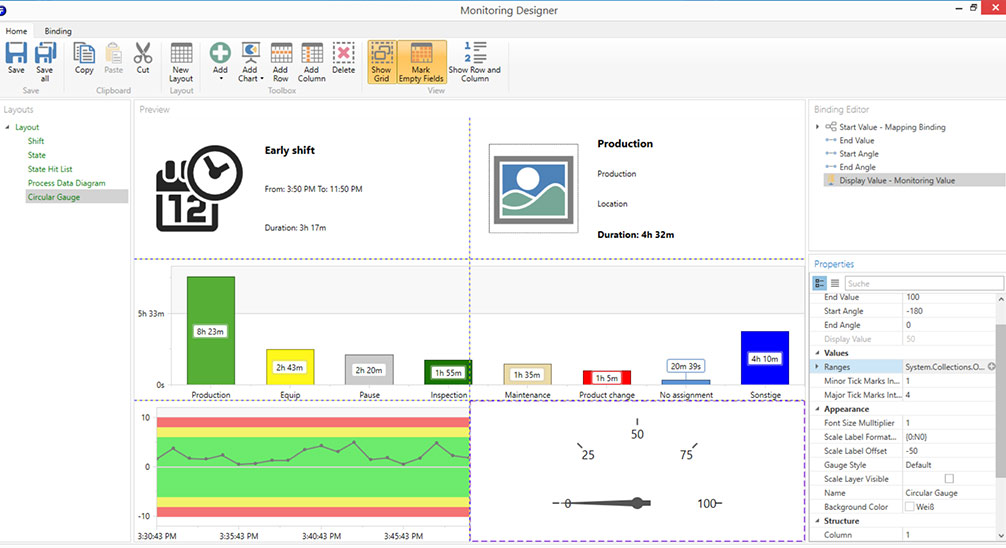

- View Designer for creating and customizing screens

- Report designer for customizing reports

Benefits for Your Corporate Success

- Core component for your modular MES solution, expandable at any time

- User can configure and flexibly expand MES

- Intuitive, high-performance software

- User can customize screen masks

- User can create individual reports quickly and easily

Quality Assurance Module (QA)

Standard

- Management of test plans

- Live trigger from MDA/PDA

- Automatic creation of test orders

- Digital checklists and forms

- Binding of peripheral devices

- Proactive information management

- Statistical process control (SPC)

Production Planning Module (PP)

Standard

- Master data management

- Article management

- Routings and bills of materials

- Production variants and versions

- Gantt chart with drag & drop function

- Scenarios and analyses

- Demand handling

- Digital planning board

- Preplanning

- Planning groups

- Setup rules

- Personnel availability planning

- Equipment availability planning

- Material availability planning

- Semaphores

- Joins

- Semi-automatic planning

- Fully automatic planning

Traceability Module (TRC)

Standard

- Acquisition of components used

- Acquisition of process values

- Assembly management

- Process locking

- Serial numbers and batch management

- Label printing

- Reports for traceability

Additional Functions

- Management of production warehouses

Maintenance Module (M)

Standard

- Resource management

- Maintenance plan management

- Live trigger from MDA/PDA

- Automatic creation of maintenance orders

- Digital forms

- Proactive information management

- Personnel deployment and requirements planning

- Alerts

- Request and task management

- MTBF/MTTR

- Autonomous maintenance

Machine Data Acquisition Module (MDA)

Standard

- Recording of machine conditions, performance and quality

- Convenient reporting:

- differentiation of rejects

- performance analysis

- MTBF/MTRR

- setup time report

- states reports

- Overall equipment effectiveness (OEE)

- Resource Log

Additional Functions

- KPI Configurator

- Process data acquisition

- Process messages

- Data archiving

- Setup rules

Production Data Aquisition Module (PDA)

Standard

- Production order management

- Routings

- Bill of material

- Various order types

- Acquisition of quantities and times

- Staff time recording

- Formula management (DNC/EDS)

- Document display

- ERP bookings

- Automatic order start

- Equipment data acquisition

Basic Module

Standard

- Audit trail

- Basic/Master data management

- User/rights management

- Multilingualism

- Report Designer

- Template Designer

Additional Functions

- Test system

- Alerts

- OPC UA Server

- ERP interface

- Cloud/BI-Connector

- Online monitoring

- Machine connection

- Classifications

- Mobile Client

- View Client

- Office Client

Fair and Flexible – You Only Buy and Pay for What You Really Need

Our seven modules are complemented by additional functions and many functionalities. This allows you to select the software components you need and you can focus on digitalizing your production step by step. We will be pleased to advise you!

Basic Module FASTEC 4 PRO: In Detail

As the foundation of the MES solution FASTEC 4 PRO, the MES Basic Module provides you with the basic configuration and administration functions and is the basis for interfaces to other systems. The integrated View Designer and the report designer allow you to customize real-time views, evaluations and reports.

The MES solution FASTEC 4 PRO can be configured flexibly. It can be perfectly tailored to your production environment. The FASTEC standard is always met. For you, this means a custom-fit and exact implementation of your requirements without jeopardizing the updateability of the system.

New functions, additional machines or further production areas can be quickly integrated into the already existing FASTEC 4 PRO system. Thanks to the careful configuration of the master data in the MES Basic Module, you can easily access them for all licensed MES modules.

Find Out More About Our Modules and Reference Solutions!

In our download area we will give you an insight into reference solutions for our customers as well as further detailed information about our modules and software solutions. Let us inspire you!

Do You Have Questions About Individual Solutions for Your Company?

With us, you benefit from extensive project experience in digital production in various industries. With over 400 customers. Worldwide. Since 1995.

Test Now!

Who We Work For

From automotive suppliers to food producers, pharmaceutical companies to toy manufacturers, from highly specialized niche suppliers, to ambitious medium-sized companies to large international corporations – more than 400 customers around the globe trust in Software for Production – made in Paderborn. Among them are: