MES Module Machine Data Acquisition (MDA)

The Most Important Functions at a Glance

- Accurate recording of machine running times and downtimes

- Assigning states automatically and/or manually, e.g. production, downtime, fault

- Automatic or manual acquisition on the touch panel, e.g. quantities, scrap quantities

- Detailed evaluations for precise weak-point analysis and identifying optimization potentials

Benefits for Your Corporate Success

- Time savings with simultaneously improved data quality thanks to automatic data acquisition

- Reducing response times to disturbances by online monitoring of the current machine status

- Many evaluations available for problem analysis at the push of a button

- Systematic recording of all downtimes, faults and short-term disturbances reliably uncovers weak points in the production process

- Exact post-calculation regarding the actually required machine running times on the basis of valid data records

Quality Assurance Module (QA)

Standard

- Management of test plans

- Live trigger from MDA/PDA

- Automatic creation of test orders

- Digital checklists and forms

- Binding of peripheral devices

- Proactive information management

- Statistical process control (SPC)

Production Planning Module (PP)

Standard

- Master data management

- Article management

- Routings and bills of materials

- Production variants and versions

- Gantt chart with drag & drop function

- Scenarios and analyses

- Demand handling

- Digital planning board

- Preplanning

- Planning groups

- Setup rules

- Personnel availability planning

- Equipment availability planning

- Material availability planning

- Semaphores

- Joins

- Semi-automatic planning

- Fully automatic planning

Traceability Module (TRC)

Standard

- Acquisition of components used

- Acquisition of process values

- Assembly management

- Process locking

- Serial numbers and batch management

- Label printing

- Reports for traceability

Additional Functions

- Management of production warehouses

Maintenance Module (M)

Standard

- Resource management

- Maintenance plan management

- Live trigger from MDA/PDA

- Automatic creation of maintenance orders

- Digital forms

- Proactive information management

- Personnel deployment and requirements planning

- Alerts

- Request and task management

- MTBF/MTTR

- Autonomous maintenance

Machine Data Acquisition Module (MDA)

Standard

- Recording of machine conditions, performance and quality

- Convenient reporting:

- differentiation of rejects

- performance analysis

- MTBF/MTRR

- setup time report

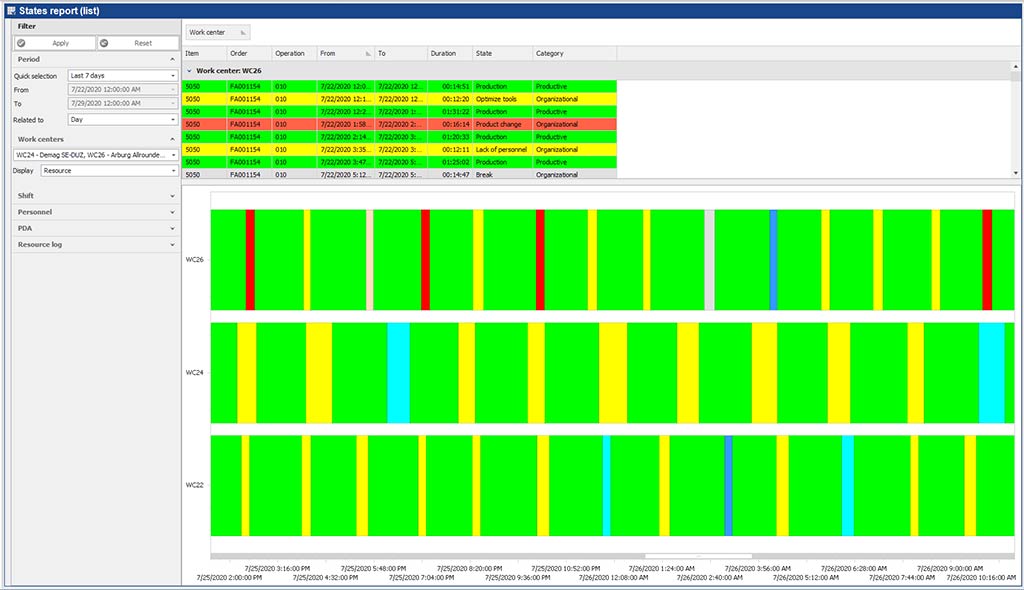

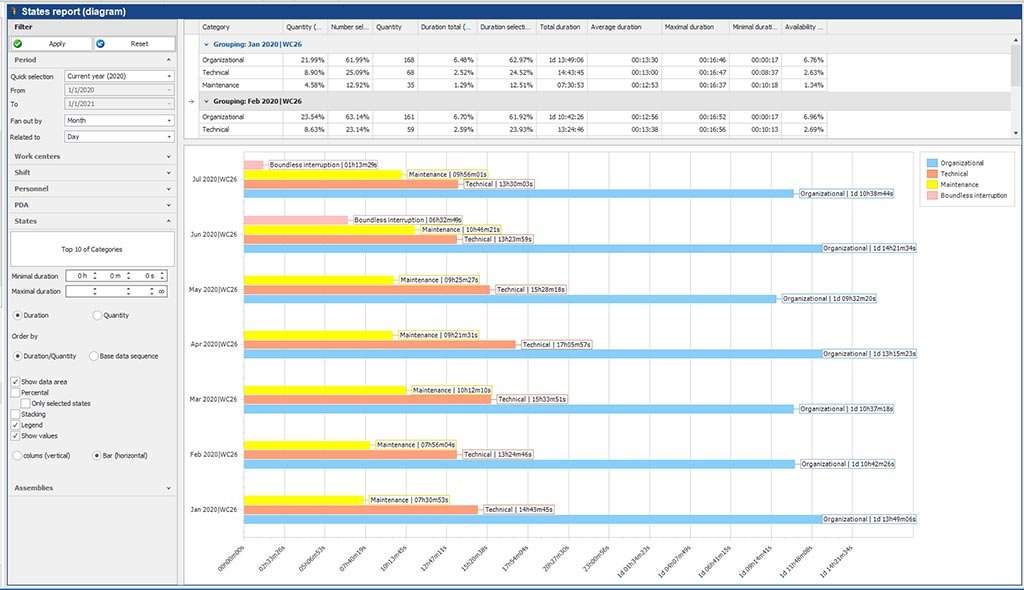

- states reports

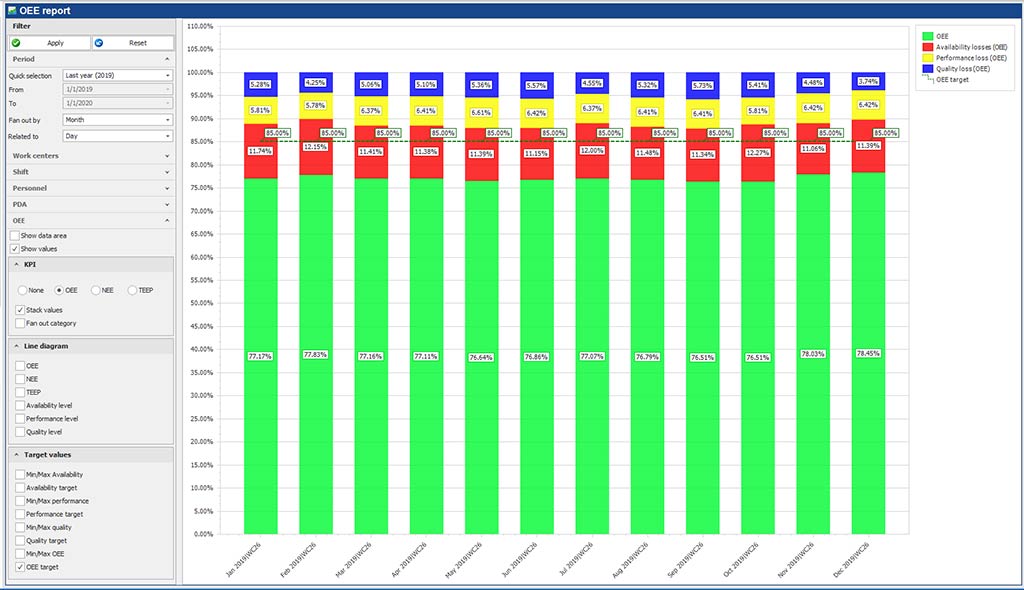

- Overall equipment effectiveness (OEE)

- Resource Log

Additional Functions

- KPI Configurator

- Process data acquisition

- Process messages

- Data archiving

- Setup rules

Production Data Aquisition Module (PDA)

Standard

- Production order management

- Routings

- Bill of material

- Various order types

- Acquisition of quantities and times

- Staff time recording

- Formula management (DNC/EDS)

- Document display

- ERP bookings

- Automatic order start

- Equipment data acquisition

Basic Module

Standard

- Audit trail

- Basic/Master data management

- User/rights management

- Multilingualism

- Report Designer

- Template Designer

Additional Functions

- Test system

- Alerts

- OPC UA Server

- ERP interface

- Cloud/BI-Connector

- Online monitoring

- Machine connection

- Classifications

- Mobile Client

- View Client

- Office Client

Fair and Flexible – You Only Buy and Pay for What You Really Need

Our seven modules are complemented by twelve additional functions and many functionalities. This allows you to select the software components you need and you can focus on digitalizing your production step by step. We will be pleased to advise you!

Module Machine Data Acquisition (MDA): In Detail

Due to the increasing degree of automation in production, losses in the area of machine and plant availability are more than ever a critical success factor. A rough estimate and trusting your gut feeling might tell you that a higher effectiveness should be possible. However, only recorded data such as historical records and evaluations provide you with reliable results in order to actually verify the presumed losses. Your measures to reduce assumed losses and to significantly increase full utilization of machine capacity can otherwise easily turn into a costly losing game. Create clarity and transparency: Use reliable data for your business venture and decision-making.

The module Machine Data Acquisition (MDA) enables you to reduce costs and at the same time to increase the effectiveness and quality of your production with a proven record of success:

- Automatic logging of machine data considerably reduces your expenditure of time compared to hand-written records. When recording quantities, running meters and downtimes, the automatic recording is also more accurate and less prone to manipulation.

- You can now generate evaluations and reports in a matter of seconds. Time-consuming manual preparation of complex MS Excel tables is a thing of the past.

- Downtimes and faults, including all reasons for downtimes, are recorded consistently and transparently in a comprehensible manner. The extensive analysis of reasons for downtimes gives you a clear idea of weaknesses in the organizational and technical operating schedules.

- Now you can precisely tackle optimization measures: This marks the beginning of sustainably increasing the degree of utilization and machine availability.

Thanks to the FASTEC 4 PRO module Machine Data Acquisition, you always stay on top of things. You can conveniently catch up on the status of individual machines, machine groups or all machines in a hall from your PC workstation. Stay up to date on what is happening in the selected supervisor area or plant, broken down into individual cost centers. From now on, you can obtain important production figures at the click of a mouse, e.g. performance, availability, quality, OEE results and quantities.

The module Machine Data Acquisition provides you with meaningful information from your production in real time. The decisive factor, however, is that the module acts like a central data supplier for additional applications. The Machine Data Acquisition often provides basic data for further modules. This is especially true for Monitoring and Alerting. The applications in the area of Maintenance, Detailed Scheduling and Traceability also obtain relevant input from the data hub MDA. In combination with other modules, a complete MES is created smoothly. You optimize your planning, control, monitoring and evaluation of your production process step by step. From assembly workstation to high-tech special machine – the decision is yours.

The smooth connection of your machines, plants and assembly workstations will give you no cause for concern. The highly flexible FASTEC interface concept permits access to all machine data in various ways. I/O modules are used to acquire digital signals, e.g. cycles or downtimes, directly at the machine. And that without intervening in the plant and machine control (PLC). In order to acquire process data and process messages from the plant and machine control (PLC), interface modules are available for a variety of common protocols and communication technologies:

- OPC

- Euromap E63

- Siemens S5/S7

- Profibus

Find Out More About Our Modules and Reference Solutions!

In our download area we will give you an insight into reference solutions for our customers as well as further detailed information about our modules and software solutions. Let us inspire you!

Are You Interested in Individual Solutions for Your Company?

With us, you benefit from extensive project experience in digital production in various industries. With over 400 customers. Worldwide. Since 1995.

Test Now!

Who We Work For

From automotive suppliers to food producers, pharmaceutical companies to toy manufacturers, from highly specialized niche suppliers, to ambitious medium-sized companies to large international corporations – more than 400 customers around the globe trust in Software for Production – made in Paderborn. Among them are: