Analyse Live Data and Become More Efficient

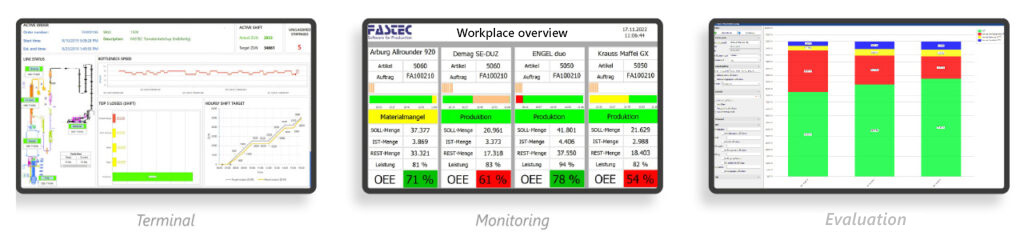

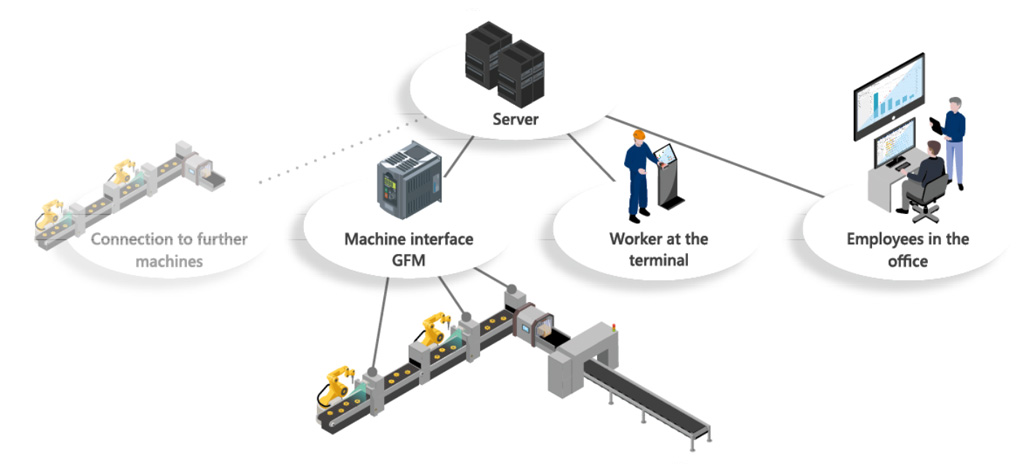

In addition to its own industrial systems, GFM offers its customers the FASTEC 4 PRO Manufacturing Execution System (MES) as a solution for increasing the productivity of their lines. This is industry-independent and can be customised to the respective production processes and provides real-time data. Thanks to its modular structure, it is also possible to implement the software modules step-by-step and as required, right through to the digitalisation of all areas of production. The system can be installed on the Human Machine Interface (HMI) of the GFM machine or on the customer’s server. Integration into the customer network means that live data, KPIs and reports can be accessed anywhere.

For us, the cooperation with GFM means that we can support even more manufacturing companies on their way to digital production. GFM customers have the great advantage of receiving a complete solution. This means that nothing is in the way of efficient and optimised production.

Linda Bauer, PR and Communications Manager at FASTEC

At GFM, the machines are designed individually in collaboration with the customer. Design reviews are used to ensure that the system meets the customer’s requirements and needs in all areas.

Successful Pilot Project Enables Standardised Acquisition Concept

The collaboration between GFM and FASTEC has already been successfully trialled in an international pilot project at a production company in the pharmaceutical industry in the Netherlands. The result is a standardised data acquisition concept that serves as a blueprint for MDA/PDA for other customers. Various extensions are possible as well.

Our pilot project has already shown how beneficial our collaboration with FASTEC is. We can now offer our customers a holistic solution to increase productivity in their production. Further projects are already being planned.

Evangelos Maurantzas, Managing Director GFM Spezialmaschinenbau GmbH

In order to map individual and complex production lines, a separate data acquisition logic was developed. The data is provided by the machine control system and processed fully automatically by MES FASTEC 4 PRO. This also includes Process data and messages that enhance the recording. The result is a fully-fledged recording of Overall Equipment Effectiveness (OEE) and the possibility of further utilising operating data for ERP postings.