Weinrich Schokolade, based in Herford, has been digitalizing its production with FASTEC since 2020. Weinrich chocolates and its own organic brands as well as private labels for various discounters are produced at the single production site. The company now has numerous varieties and even vegan chocolate in its range and is very well known for this in the region.

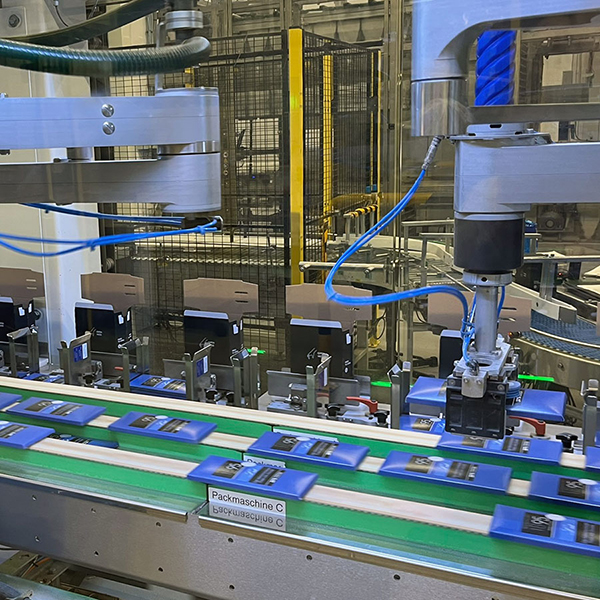

After a brief introduction to the company, we went straight into production. There we were shown the chocolate manufacturing process: from the raw mass to the fully automatic packaging system and where FASTEC 4 PRO is used in production. We then took a closer look at data acquisition and reporting at the Weinrich Chocolate Factory.

This allowed for an authentic insight into working with our software especially for the many interested visitors – a successful event in the company’s beautiful building, which combines history with modernity.

There have never been so many regional companies at one of our ON-SITE events, and we are very pleased about that. The OWL region has a lot to offer in terms of industry and we are happy to also support small and medium-sized companies in taking the step into digital data acquisition.

Linda Bauer, PR & Communications Manager at FASTEC

We would like to thank our customer Weinrich Schokolade for this opportunity!