MES-Modul Traceability (TRC)

Die wichtigsten Funktionen auf einen Blick

- Erfassen, Zusammenführen und Speichern von Prozess- und Materialdaten

- Direkte Übernahme von Serien- und Chargennummern aus den Maschinensteuerungen

- Einlesen von Serien- und Chargennummern mittels Scanner

- Komfortable Such- und Auswertungsmasken:

- Produkthistorie inklusive Forward und Backward Tracking

- Prozessregelkarten, Histogramme

- Prozessdurchlaufquote (First Pass Yield)

- Durchlaufzeiten

Nutzen für Ihren Unternehmenserfolg

- Sichere Fertigung durch lückenlose Traceability

- Vollständiger Überblick über die gesamte Wertschöpfungskette

- Lückenlose Dokumentation des gesamten Produktionsprozesses

- Umfassende Auswertung der erfassten und dauerhaft protokollierten Daten

- Eingrenzung fehlerhafter Produkte im Schadensfall

- Minimierung von Rückrufkosten

Modul Qualitätssicherung (QS)

Standard

- Verwaltung von Prüfplänen

- Live-Trigger aus MDE/BDE

- Automatische Erstellung von Prüfaufträgen

- Digitale Checklisten und Formulare

- Anbindung von Peripheriegeräten

- Proaktives Informationsmanagement

- Stichproben (SPC)

Modul Produktionsplanung (PP)

Standard

- Stammdatenverwaltung

- Artikelverwaltung

- Arbeitspläne und Stücklisten

- Fertigungsvarianten und -versionen

- Gantt-Chart mit Drag & Drop-Funktion

- Szenarien und Auswertungen

Zusatzfunktionen

- Bedarfshandling

- Digitale Plantafel

- Vorplanung

- Planungsgruppen

- Rüstregeln

- Personalverfügbarkeitsplanung

- Betriebsmittelverfügbarkeitsplanung

- Materialverfügbarkeitsplanung

- Semaphoren

- Joins

- Halbautomatische Planung

- Vollautomatische Planung

Modul Traceability (TRC)

Standard

- Erfassung von eingesetzten Komponenten

- Erfassung von Prozesswerten

- Baugruppenverwaltung

- Prozessverriegelung

- Seriennummern und Chargenverwaltung

- Etikettendruck

- Auswertungen zur Rückverfolgbarkeit

- Verwaltung von Produktionslägern

Modul Instandhaltung (INST)

Standard

- Ressourcenverwaltung

- Verwaltung von Instandhaltungsplänen

- Automatische Erstellung von Instandhaltungsaufträgen

- Digitale Formulare

- Proaktives Informationsmanagement

- Personaleinsatz- und Bedarfsplanung

- Alarmierungen

- Anfragen- und Aufgabenverwaltung

- MTBF/MTTR

- Autonome Instandhaltung

Modul Maschinendatenerfassung (MDE)

Standard

- Erfassung von Maschinenzuständen, Leistung und Qualität

- Komfortable Auswertungen

- Ausschussdifferenzierung

- Leistungsauswertung

- MTBF/MTTR

- Rüstzeitauswertung

- Zustandsauswertung

- Overall Equipment Effectiveness

(OEE) - Ressourcenlogbuch

Zusatzfunktionen

- KPI-Konfigurator

- Prozessdatenerfassung

- Prozessmeldungen

- Datenarchivierung

- Rüstregeln

Modul Betriebsdatenerfassung (BDE)

Standard

- Fertigungsauftragsmanagement

- Arbeitspläne

- Stücklisten

- Auftragsarten

- Erfassung von Mengen und Zeiten

Zusatzfunktionen

- Personalzeiterfassung

- Rezepturverwaltung (DNC/EDS)

- Dokumentenanzeige

- ERP-Buchungen

- Automatischer Auftragsstart

- Betriebsmittel-Datenerfassung

Basis-Modul

Standard

- Audit Trail

- Basis-/Stammdatenverwaltung

- Benutzer-/Rechteverwaltung

- Mehrsprachigkeit

- Report Designer

- Template Designer

Zusatzfunktionen

- Testsystem

- Alarmierungen

- OPC UA Server

- ERP-Schnittstelle

- Cloud/BI-Connector

- Online-Monitoring

- Maschinenanbindung

- Klassifizierungen

- Mobile Client

- View Client

- Office Client

Fair und flexibel – Sie erwerben nur, was Sie benötigen

Unsere sieben Module werden durch Zusatzfunktionen und viele Funktionalitäten ergänzt. Dadurch haben Sie die Möglichkeit, die Software-Bausteine auszuwählen, welche Sie benötigen und können die Digitalisierung Ihrer Fertigung Schritt für Schritt ausbauen. Wir beraten Sie gerne!

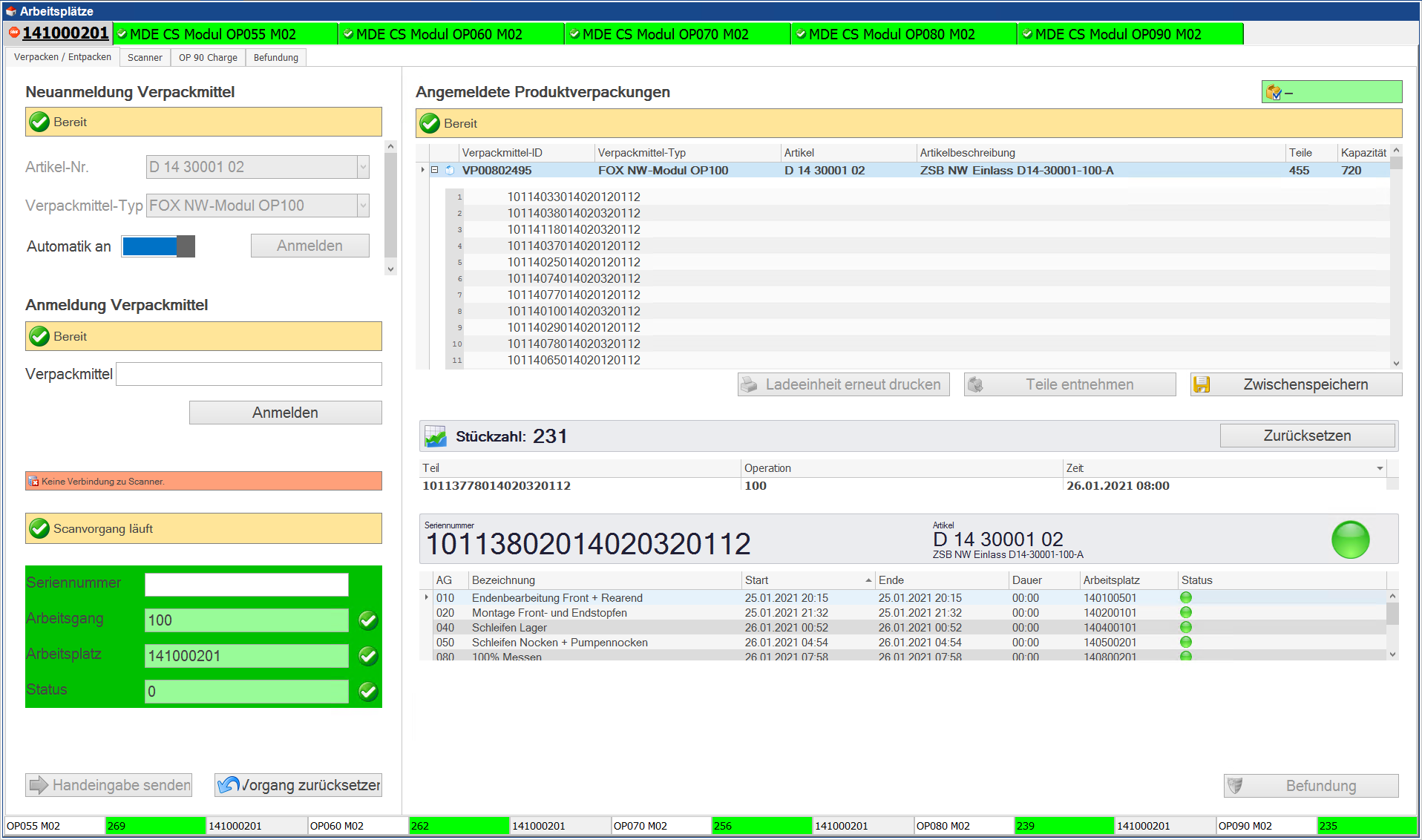

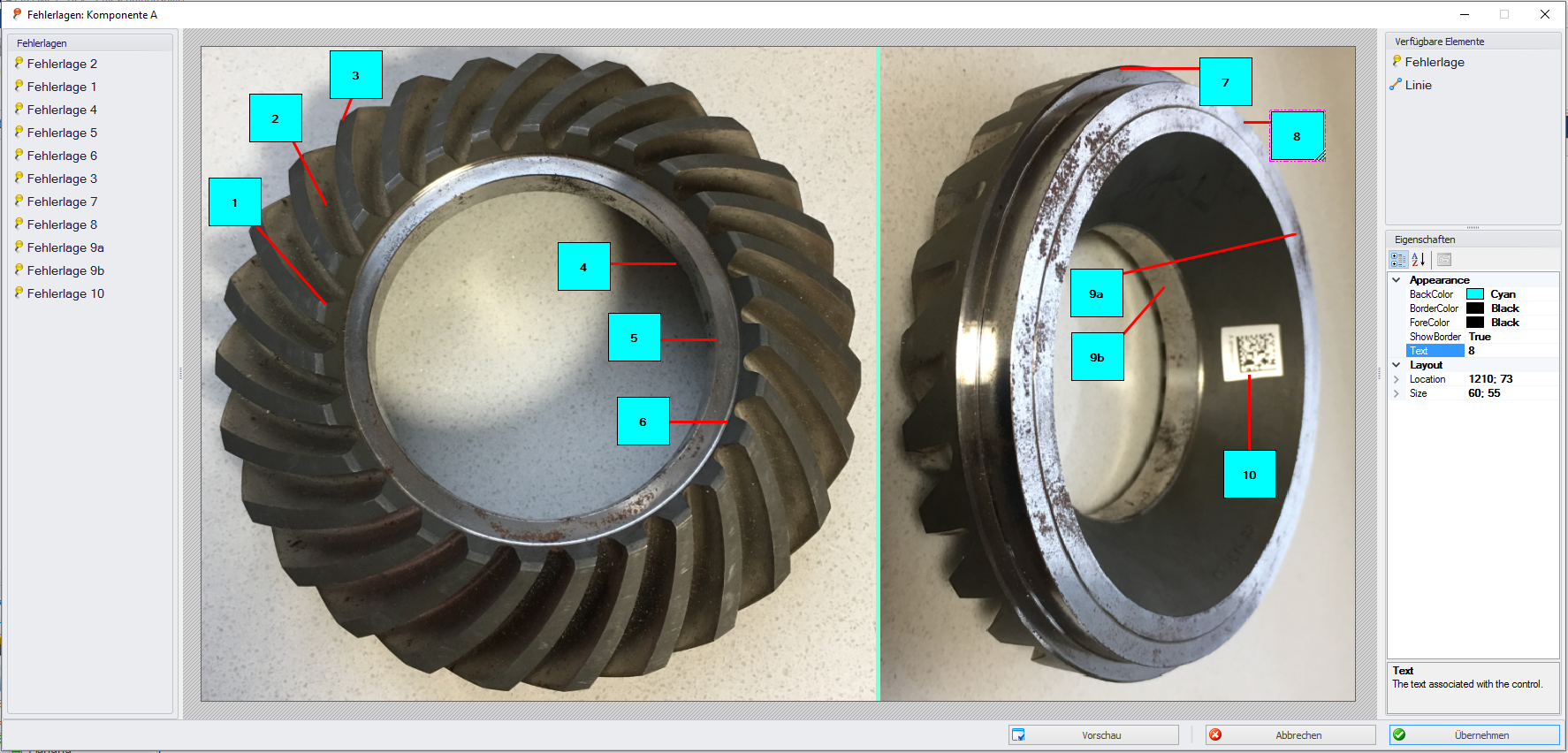

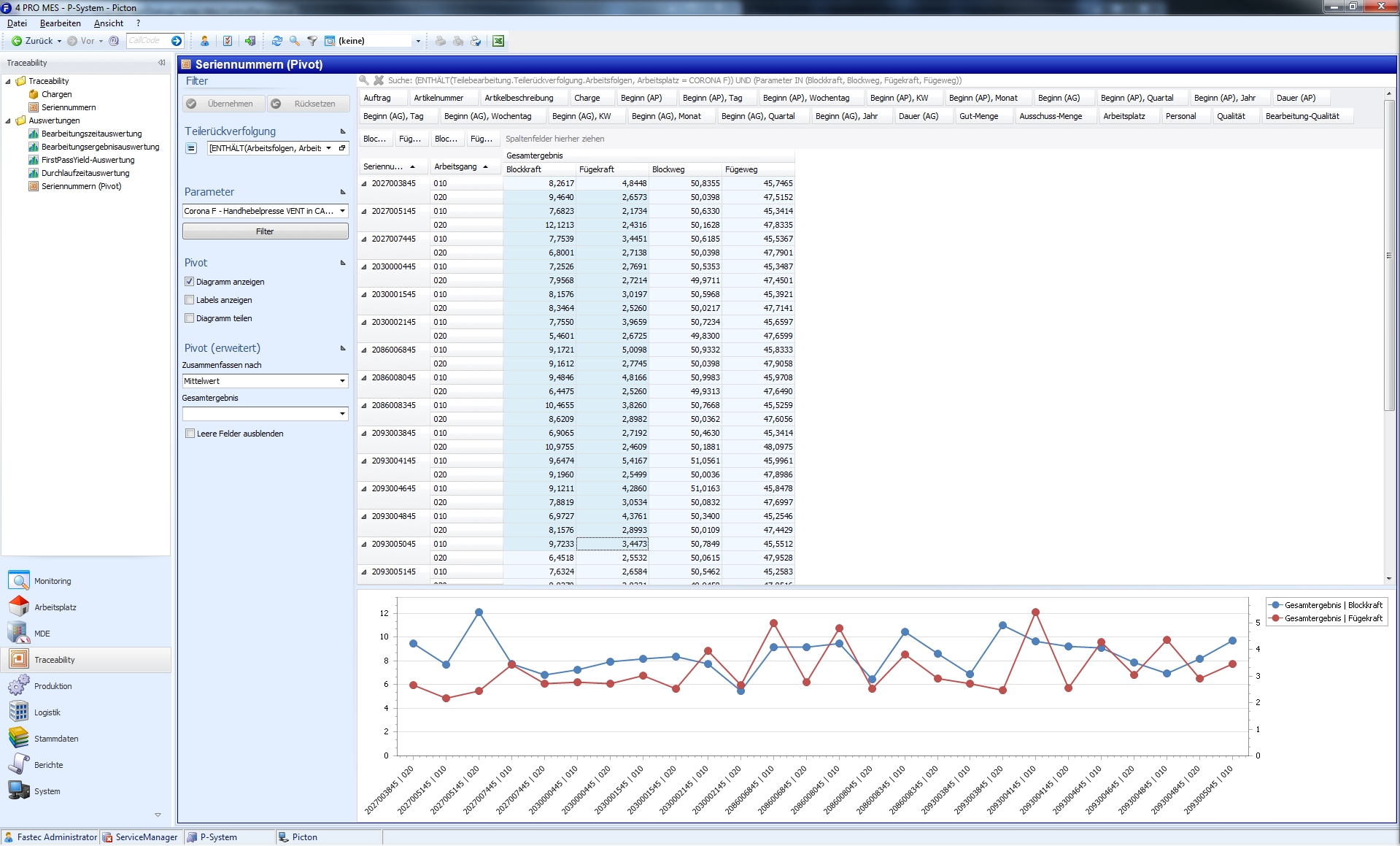

Modul Traceability (TRC): Im Detail

Verschaffen Sie sich einen verlässlichen und vollständigen Überblick über Ihre gesamte Wertschöpfungskette: Mit dem Modul Traceability (TRC) können Sie dank Forward/Backward Tracking, Histogrammen, Regelkarten etc. die Stabilität Ihrer Produktionsprozesse jederzeit beurteilen. Umfangreiche Auswertungen wie zum First Pass Yield, generellen Durchlaufzeiten, Bearbeitungsergebnisse usw. können Sie nun detailliert beurteilen.

Alle relevanten Prozess- und Materialdaten des Produktionsprozesses werden erfasst und dauerhaft zur jeweiligen Produktkennung gespeichert. Für die Produkt- und Teilekennung kann das FASTEC 4 PRO-Modul Traceability (TRC) die Serien- und Chargennummern direkt aus der Maschinensteuerung übernehmen oder die Daten mittels Barcode Scanner einlesen. Der Nummerngenerator erzeugt fortlaufende Seriennummern nach Vorgabe individueller Nummernkreise, die das System eigenständig generiert und z. B. als Etiketten druckt.

Lesen Sie auch unseren Fachbeitrag in „IT & Production“: „Rückverfolgbarkeit nutzen: Chargen und Bauteile genau im Blick“.

Forward Traceability

Bei Produktfehlern betroffene Produkte rechtzeitig eingrenzen – sogar bereits vor dem Versand

Backward Traceability

Bei Produktfehlern die ursächlichen Prozesse, Maschinen, Betriebsmittel, verwendete Chargen identifizieren

Erfahren Sie mehr über unsere Module und Referenzlösungen!

In unserem Download-Bereich erhalten Sie Einblicke in Referenzlösungen unserer Kunden sowie weiterführende Detailinformationen zu unseren Modulen und Software-Lösungen. Lassen Sie sich inspirieren!

Haben Sie Interesse an individuellen Lösungen für Ihr Unternehmen?

Mit uns profitieren Sie von umfangreicher Projekterfahrung in der digitalen Fertigung verschiedener Branchen. Bei über 400 Kunden. Weltweit. Seit 1995.

Haben Sie Interesse an individuellen Lösungen für Ihr Unternehmen?

Mit uns profitieren Sie von umfangreicher Projekterfahrung in der digitalen Fertigung verschiedener Branchen. Bei über 400 Kunden. Weltweit. Seit 1995.

Für wen wir arbeiten

Vom Automobilzulieferer über Lebensmittelproduzenten, Pharmaunternehmen bis hin zum Spielwarenhersteller, vom hochspezialisierten Nischenanbieter, über den ambitionierten Mittelständler bis hin zum international aufgestellten Großkonzern – über 400 Kunden rund um den Globus setzen auf Software for Production – made in Paderborn. Darunter auch: