MES-Modul Betriebsdatenerfassung

Die wichtigsten Funktionen auf einen Blick

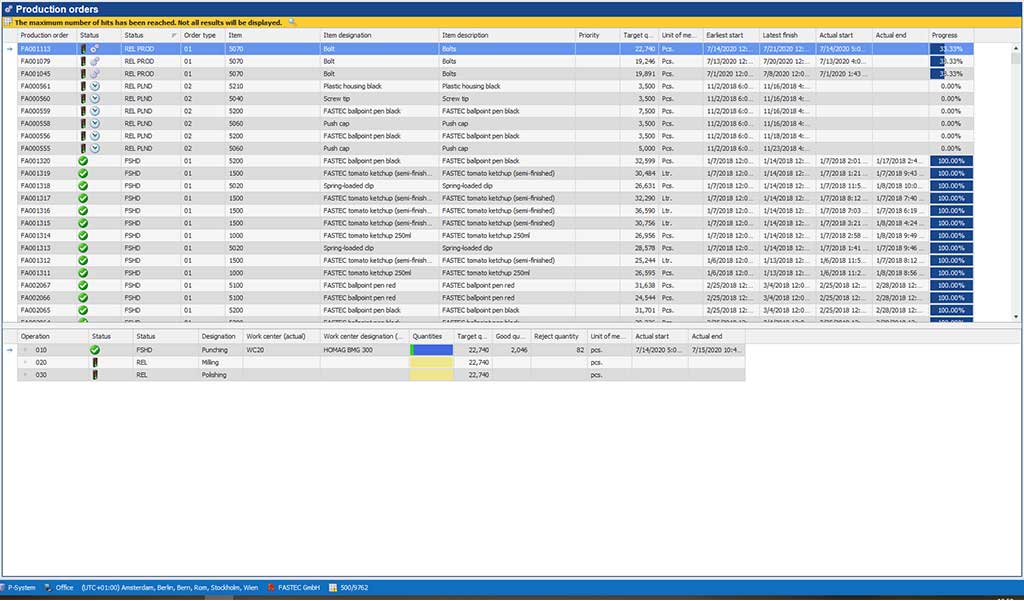

- Übersichtliches Verwalten und priorisiertes Abarbeiten von Fertigungsaufträgen

- Digitales An- und Abmelden von Aufträgen an der Maschine oder am Arbeitsplatz

- Automatisches oder manuelles Rückmelden z. B. von produzierten Mengen, Ausschuss und Zählerständen

- Echtzeitbasierte Anzeige des Auftragsfortschritts

- Detailliertes Erfassen und Anzeigen verschiedener auftrags- und artikelbezogener Daten, z. B. Stückzahlen, Soll-Werte, Ist-Werte, Restmengen und Ausschuss

- Wirksame Unterstützung bei der überlappenden Fertigung von Arbeitsgängen

- Präzise Hochrechnung der Restlaufzeit zum voraussichtlichen Auftragsende

Nutzen für Ihren Unternehmenserfolg

- Papierlose Anmeldung von Aufträgen direkt an der Maschine

- Beschleunigte Abläufe durch Online-Kommunikation

- Transparente Produktionsprozesse durch automatisch erfasste Auftragsdaten

- Schnelles Erkennen von Ablaufstörungen in der Produktion

- Sofortige Visualisierung von Abweichungen zwischen Soll- und Ist-Werten

- Spürbare Zeitersparnis und Vermeidung von Übermittlungsfehlern durch automatische Auftragsrückmeldung an das ERP-/PPS-System

Modul Qualitätssicherung (QS)

Standard

- Verwaltung von Prüfplänen

- Live-Trigger aus MDE/BDE

- Automatische Erstellung von Prüfaufträgen

- Digitale Checklisten und Formulare

- Anbindung von Peripheriegeräten

- Proaktives Informationsmanagement

- Stichproben (SPC)

Modul Produktionsplanung (PP)

Standard

- Stammdatenverwaltung

- Artikelverwaltung

- Arbeitspläne und Stücklisten

- Fertigungsvarianten und -versionen

- Gantt-Chart mit Drag & Drop-Funktion

- Szenarien und Auswertungen

Zusatzfunktionen

- Bedarfshandling

- Digitale Plantafel

- Vorplanung

- Planungsgruppen

- Rüstregeln

- Personalverfügbarkeitsplanung

- Betriebsmittelverfügbarkeitsplanung

- Materialverfügbarkeitsplanung

- Semaphoren

- Joins

- Halbautomatische Planung

- Vollautomatische Planung

Modul Traceability (TRC)

Standard

- Erfassung von eingesetzten Komponenten

- Erfassung von Prozesswerten

- Baugruppenverwaltung

- Prozessverriegelung

- Seriennummern und Chargenverwaltung

- Etikettendruck

- Auswertungen zur Rückverfolgbarkeit

- Verwaltung von Produktionslägern

Modul Instandhaltung (INST)

Standard

- Ressourcenverwaltung

- Verwaltung von Instandhaltungsplänen

- Automatische Erstellung von Instandhaltungsaufträgen

- Digitale Formulare

- Proaktives Informationsmanagement

- Personaleinsatz- und Bedarfsplanung

- Alarmierungen

- Anfragen- und Aufgabenverwaltung

- MTBF/MTTR

- Autonome Instandhaltung

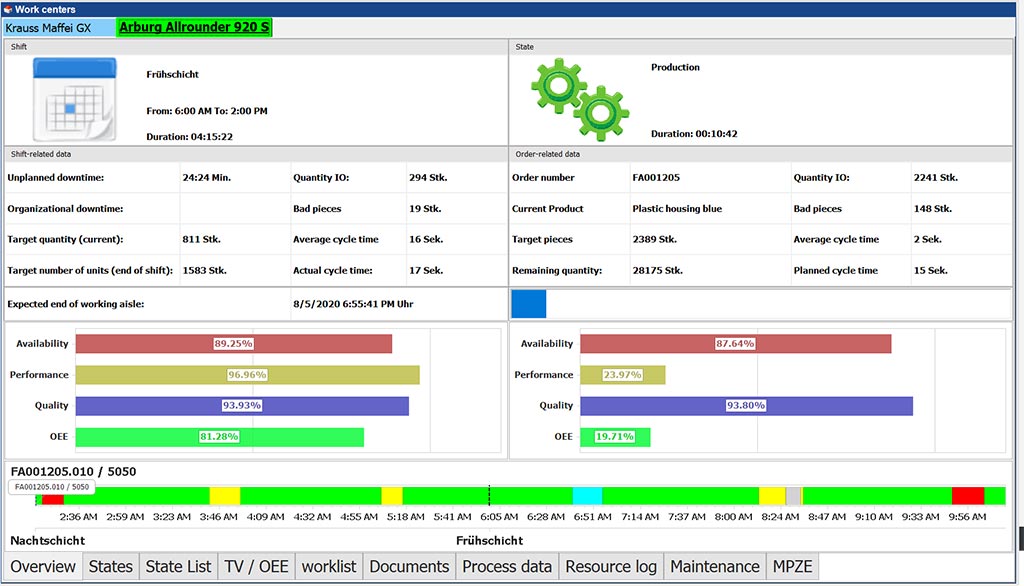

Modul Maschinendatenerfassung (MDE)

Standard

- Erfassung von Maschinenzuständen, Leistung und Qualität

- Komfortable Auswertungen

- Ausschussdifferenzierung

- Leistungsauswertung

- MTBF/MTTR

- Rüstzeitauswertung

- Zustandsauswertung

- Overall Equipment Effectiveness

(OEE) - Ressourcenlogbuch

Zusatzfunktionen

- KPI-Konfigurator

- Prozessdatenerfassung

- Prozessmeldungen

- Datenarchivierung

- Rüstregeln

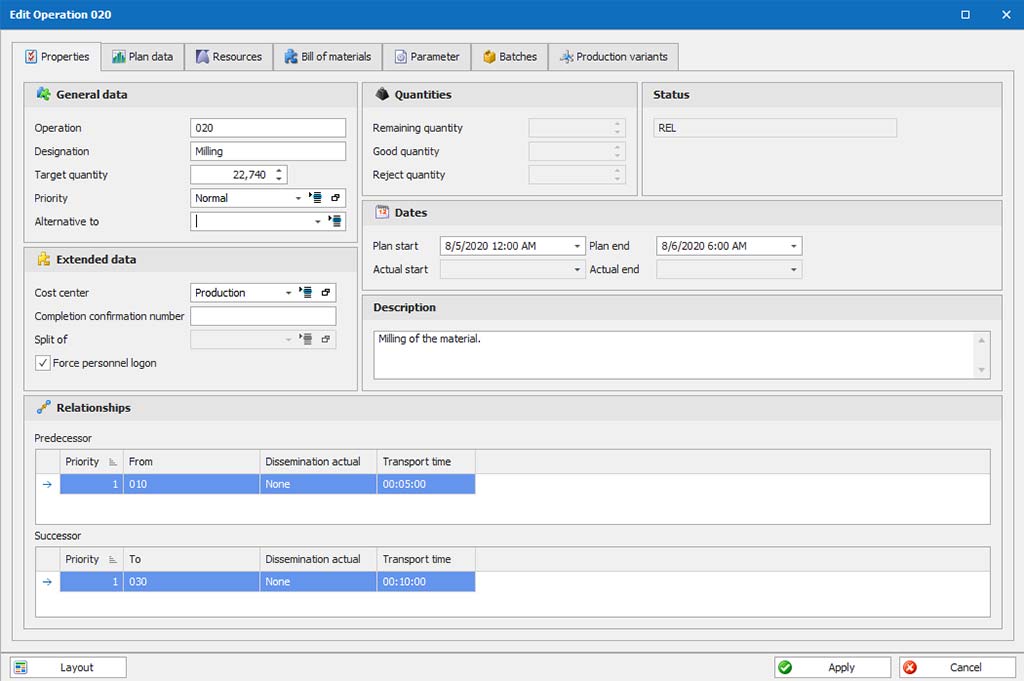

Modul Betriebsdatenerfassung (BDE)

Standard

- Fertigungsauftragsmanagement

- Arbeitspläne

- Stücklisten

- Auftragsarten

- Erfassung von Mengen und Zeiten

Zusatzfunktionen

- Personalzeiterfassung

- Rezepturverwaltung (DNC/EDS)

- Dokumentenanzeige

- ERP-Buchungen

- Automatischer Auftragsstart

- Betriebsmittel-Datenerfassung

Basis-Modul

Standard

- Audit Trail

- Basis-/Stammdatenverwaltung

- Benutzer-/Rechteverwaltung

- Mehrsprachigkeit

- Report Designer

- Template Designer

Zusatzfunktionen

- Testsystem

- Alarmierungen

- OPC UA Server

- ERP-Schnittstelle

- Cloud/BI-Connector

- Online-Monitoring

- Maschinenanbindung

- Klassifizierungen

- Mobile Client

- View Client

- Office Client

Fair und flexibel – Sie erwerben nur, was Sie benötigen

Unsere sieben Module werden durch Zusatzfunktionen und viele Funktionalitäten ergänzt. Dadurch haben Sie die Möglichkeit, die Software-Bausteine auszuwählen, welche Sie benötigen und können die Digitalisierung Ihrer Fertigung Schritt für Schritt ausbauen. Wir beraten Sie gerne!

Modul Betriebsdatenerfassung: Im Detail

Tabellarisch und grafisch aufgearbeitete Auswertungen erhalten Sie jederzeit auf Abruf. Nach Belieben können Sie Auftrags- und Artikeldaten, Ausschusswerte, Vergleiche von Soll- und Ist-Daten bei Produktions- oder Rüstdaten einsehen. Dabei sind Sie in Ihrer Auswahl nicht eingeschränkt: Jeder Nutzer kann nach seinen individuellen Zielen entscheiden, welche Daten er benötigt und nach welchen Kriterien diese analysiert werden sollen.

Lesen Sie dazu unsere Fachartikel

- MES als Grundlage der Smart Factory

- MES Lösungen: Mehr Transparenz für eine zukunftsfähige Produktion

- MES Manufacturing Execution System: Der digitale Vorsprung für Ihre Produktion

- Best Practice Digitalisierung: Einblicke in individuelle Lösungswege mittelständischer Unternehmen (KMU)

- Die Digitalisierung macht zukunftsfähiger und zahlt sich aus. 6 Werkzeuge für die digitale Fabrik

Erfahren Sie mehr über unsere Module und Referenzlösungen!

In unserem Download-Bereich erhalten Sie Einblicke in Referenzlösungen unserer Kunden sowie weiterführende Detailinformationen zu unseren Modulen und Software-Lösungen. Lassen Sie sich inspirieren!

Haben Sie Interesse an individuellen Lösungen für Ihr Unternehmen?

Mit uns profitieren Sie von umfangreicher Projekterfahrung in der digitalen Fertigung verschiedener Branchen. Bei über 400 Kunden. Weltweit. Seit 1995.

Haben Sie Interesse an individuellen Lösungen für Ihr Unternehmen?

Mit uns profitieren Sie von umfangreicher Projekterfahrung in der digitalen Fertigung verschiedener Branchen. Bei über 400 Kunden. Weltweit. Seit 1995.

Jetzt Kontakt aufnehmen!

Möchten Sie direkt einen Termin vereinbaren?

Für wen wir arbeiten

Vom Automobilzulieferer über Lebensmittelproduzenten, Pharmaunternehmen bis hin zum Spielwarenhersteller, vom hochspezialisierten Nischenanbieter, über den ambitionierten Mittelständler bis hin zum international aufgestellten Großkonzern – über 400 Kunden rund um den Globus setzen auf Software for Production – made in Paderborn. Darunter auch: