Prozessdatenerfassung (PDE) – Maschinendaten in Echtzeit!

Die wichtigsten Funktionen auf einen Blick

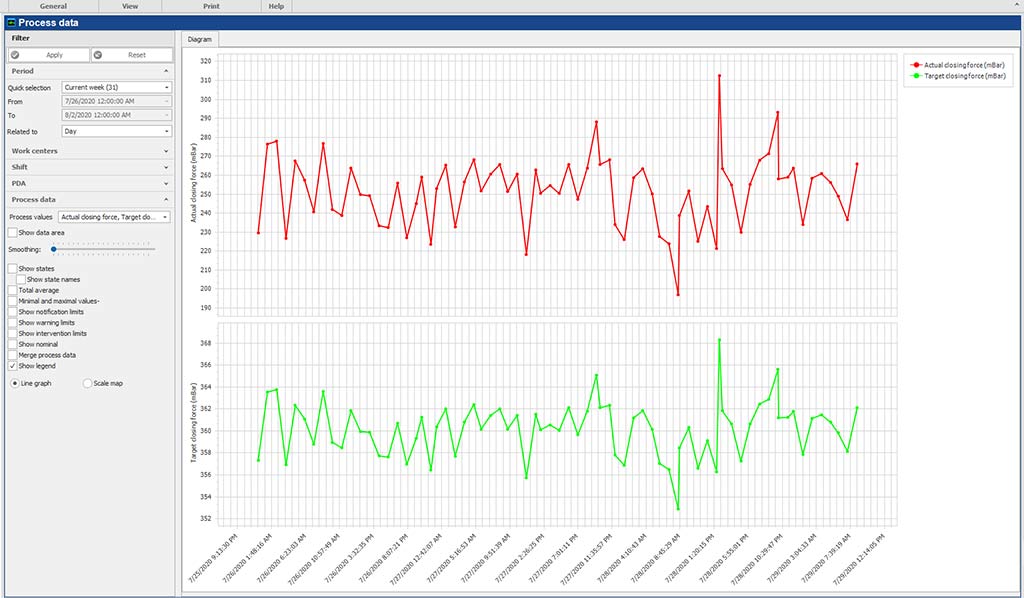

- Erfassung, Protokollierung und Speicherung konfigurierter Prozesswerte

- Frei konfigurierbarer zeitlicher Trigger aller Prozesswerte

- Überwachung der Toleranz- und Eingriffsgrenzen und Auslösen von Meldungen sowie Alarmen

- Einblendung von OEE-Zuständen in der Gesamtdarstellung

- Sofortige Verfügbarkeit grafischer und tabellarischer Auswertungen auf Knopfdruck

- Drucken sowie Datenexport nach Excel

Nutzen für Ihren Unternehmenserfolg

- Permanente Überwachung der konfigurierten Prozesswerte auf Abweichungen

- Dauerhafte Speicherung aller Prozessdaten in einer Datenbank

- Komfortable Auswertungen inklusive Zeitfilter, Schichtfilter und Artikelfilter auch für längere Zeiträume in grafischer und tabellarischer Form

- Verlässliche Dokumentation von Prozessen in Form von Protokollen, Logbüchern und Diagrammen

Zusatzfunktion Prozessdatenerfassung: Im Detail

Sie möchten mehr über unsere MES-Module und Referenzlösungen erfahren?

Informationen zu unserer modularen Software-Lösung FASTEC 4 PRO, achtteilige Whitepaper-Serie „MES und Industrie 4.0“, Anwenderberichte …

Unsere MES-Module – passgenau und mit zentraler Datenbasis

Vielfältige Anforderungen – eine Lösung: Aufbauend auf dem MES-Basis-Modul können alle FASTEC 4 PRO-Module nach Ihren Anforderungen individuell miteinander kombiniert werden. Dabei greifen die einzelnen MES-Module auf eine gemeinsame und einheitliche Datenbasis zu. So haben Sie immer durchgängige Daten – es gibt keine Schnittstellen

zwischen den Modulen und keine doppelte Datenhaltung. Durch den modularen Aufbau ist zudem eine schrittweise und bedarfsorientierte Implementierung der Softwarebausteine bis hin zu einer alle Bereiche umfassenden Digitalisierung Ihrer kompletten Fertigung an einem oder mehreren Standorten möglich.

Haben Sie Interesse an oder Fragen zu Lösungen für Ihr Unternehmen?

Für wen wir arbeiten

Vom Automobilzulieferer über Lebensmittelproduzenten, Pharmaunternehmen bis hin zum Spielwarenhersteller, vom hochspezialisierten Nischenanbieter, über den ambitionierten Mittelständler bis hin zum international aufgestellten Großkonzern – über 400 Kunden rund um den Globus setzen auf Software for Production – made in Paderborn. Darunter auch: