Monitoring – Ihr umfassender Überblick

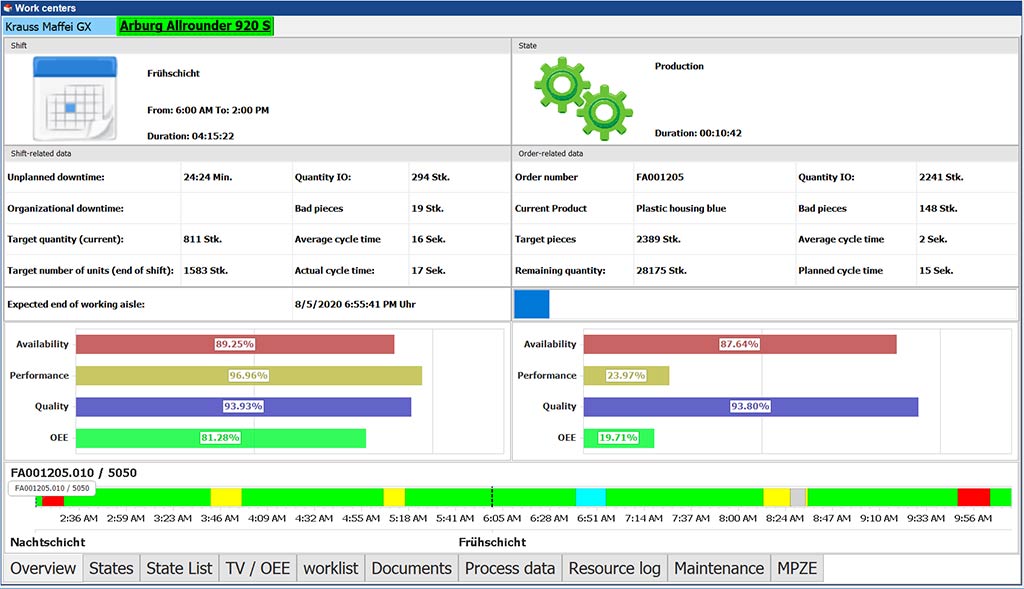

Zustände einzelner Maschinen, aktuelle Produktionskennzahlen und Alarmhinweise – alles im Blick, umfassend und in Echtzeit.

Die wichtigsten Funktionen auf einen Blick

- Grafischer Maschinenpark mit Echtzeitdaten

- Tabellarische und grafische Views

- Slide Views mit zeitlich individuell einstellbaren wechselnden Ansichten

- Laufschriften als Informationstrigger für die Mitarbeiter

- Einfache Konfiguration individueller Ansichten für jeden Einsatzbereich

Nutzen für Ihren Unternehmenserfolg

- Überblick über die gesamte Produktion in Echtzeit

- Präzise Informationen ermöglichen unmittelbares Reagieren auf Ereignisse und Störungen

- Optisch ansprechend und eindeutig aufbereitete Daten bilden valide Entscheidungsgrundlage

- Einfaches, schnelles und sicheres Konfigurieren von Ansichten durch den jeweiligen Nutzer

Zusatzfunktion Monitoring: Im Detail

Mit der Zusatzfunktion Monitoring lassen Sie sich und Ihrem Team die benötigten Informationen problemlos auf unterschiedlichen Geräten anzeigen – am Produktionsterminal, speziellen Monitoren oder auf Großbildschirmen. Eingebettet in das Hallenlayout behalten Sie Maschinenzustände im Blick, haben valide visualisierte auftragsbezogene Prozessdaten parat oder kommunizieren wichtige Informationen z. B. der Geschäftsführung oder der Betriebsleitung.

Die Darstellung auf den ausgewählten Bildschirmen können Sie individuell und abhängig vom Einsatzort gestalten. Bereits im Standardumfang liefert Ihnen die Zusatzfunktion Monitoring zahlreiche Standard-Bildschirmmasken. Mit Hilfe der Zusatzfunktion View Designer können Sie weitere spezielle Ansichten erstellen, z. B. die Zusammenfassung von Produktionsleistungen der letzten acht Stunden für Ihre Geschäftsleiterbesprechung oder aktuelle Zustands- und Fehlermeldungen für Ihre Qualitätssicherung.

Informationen dürfen idealerweise keiner Einschränkung unterliegen. Sie müssen in Echtzeit verfügbar sein und Sie in die Lage versetzen, situativ das Relevante zu erfahren sowie Zusätzliches einzubinden. Mit der Zusatzfunktion Monitoring bieten sich Ihnen diese Möglichkeiten. Auftragsbezogene Informationen, aktuelle Produktionsdaten sowie individuell gestaltete Reports bilden nur einen Teil der Darstellungsmöglichkeiten ab. Zusätzlich können Sie aktuelle KPIs als tabellarische oder grafische Ansichten in periodisch wechselnder Abfolge visualisieren. Auch andere Elemente, wie z. B. Webseiten und Newsticker, können Sie über die Monitoring-Zusatzfunktion ohne weiteres darstellen und damit für erhöhte Transparenz sorgen.

Definierte Prinzipien der Lean Production sind unter anderem Kompetenzen und Verantwortung zusammenzuführen, in Netzwerken zu arbeiten und Abläufe zu synchronisieren. So entsteht Transparenz. Und diese wiederum resultiert in einem kontinuierlichen Verbesserungsprozess.

Unverzichtbare Grundvoraussetzung dafür ist jedoch die Integration aller in die Produktion involvierten Mitarbeiter durch produktionsrelevante Informationen. Wie die Zusatzfunktion Monitoring auf dem Weg Richtung Industrie 4.0 eingesetzt wurde, hat Diehl Controls in Wangen erfolgreich bewiesen. Bereits 2015 wurde das Unternehmen zur Fabrik des Jahres gekürt. Erfahren Sie mehr in unserem Anwenderbericht.

Sie möchten mehr über unsere MES-Module und Referenzlösungen erfahren?

Unsere MES-Module – passgenau und mit zentraler Datenbasis

Vielfältige Anforderungen – eine Lösung: Aufbauend auf dem MES-Basis-Modul können alle FASTEC 4 PRO-Module nach Ihren Anforderungen individuell miteinander kombiniert werden. Dabei greifen die einzelnen MES-Module auf eine gemeinsame und einheitliche Datenbasis zu. So haben Sie immer durchgängige Daten – es gibt keine Schnittstellen

zwischen den Modulen und keine doppelte Datenhaltung. Durch den modularen Aufbau ist zudem eine schrittweise und bedarfsorientierte Implementierung der Softwarebausteine bis hin zu einer alle Bereiche umfassenden Digitalisierung Ihrer kompletten Fertigung an einem oder mehreren Standorten möglich.

Haben Sie Interesse an oder Fragen zu Lösungen für Ihr Unternehmen?

Für wen wir arbeiten

Vom Automobilzulieferer über Lebensmittelproduzenten, Pharmaunternehmen bis hin zum Spielwarenhersteller, vom hochspezialisierten Nischenanbieter, über den ambitionierten Mittelständler bis hin zum international aufgestellten Großkonzern – über 400 Kunden rund um den Globus setzen auf Software for Production – made in Paderborn. Darunter auch: