MES-Modul Qualitätssicherung (QS)

Die wichtigsten Funktionen auf einen Blick

- Frei konfigurierbare Prüfart

- Unterstützung von In-Prozess-Kontrollen und Arbeitsplatzkontrollen

- Flexible Konfiguration unterschiedlicher Prüfpläne

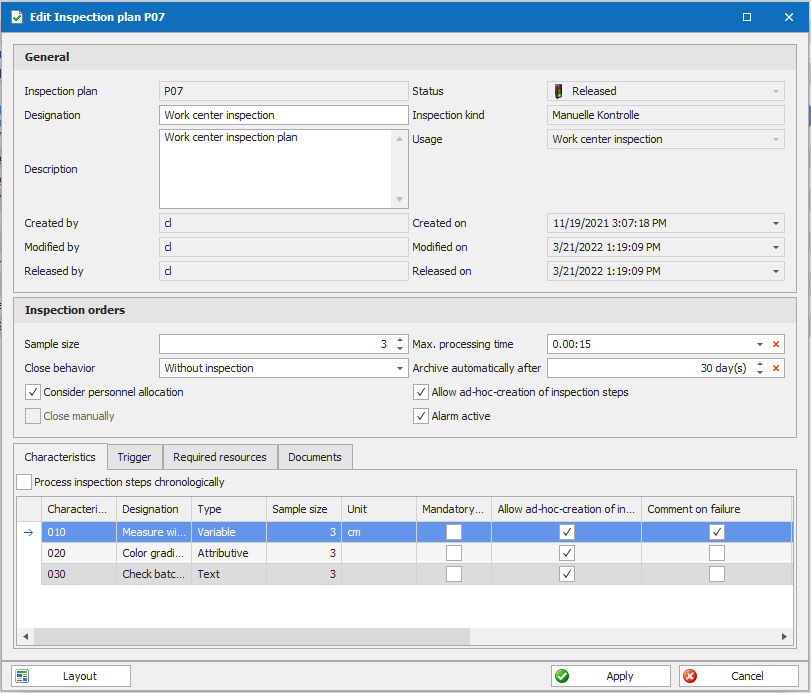

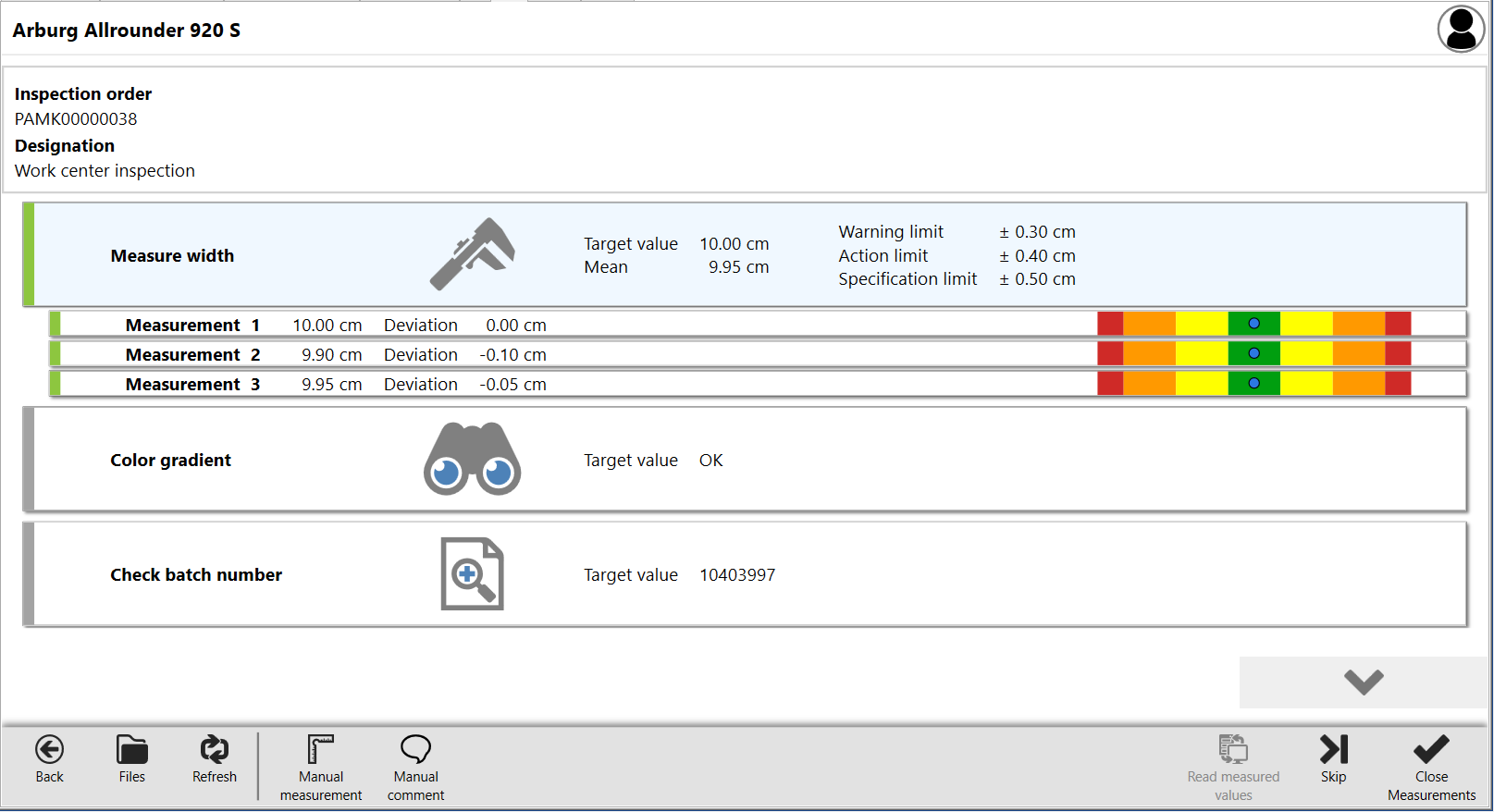

- Detaillierte Festlegung von Prüfmerkmalen inklusive Vorgabe des Prüfmittels, Bestimmung von Grenztypen, einzuhaltenden Grenzen und Handlungsaufforderungen

- Prüfplanerstellung und -bearbeitung inklusive konfigurierbarem Statusschema für Zustandsübergänge und Rechtevergabe

- Definition unterschiedlicher Trigger für die Prüfschritte, z. B. zeitbasiert oder bezogen auf den Fertigungsauftrag

- Personaleinsatz- und -bedarfsplanung für Prüfaufträge

Nutzen für Ihren Unternehmenserfolg

- Einfache Integration in FASTEC 4 PRO

- Kompatibilität mit allen FASTEC 4 PRO Modulen und Zusatzfunktionen

- Digitalisierung der In-Prozess-Kontrollen Ihrer Artikel

- Automatisierte Prüfauftragserstellung auf Basis Ihrer Auftragsdaten

- Flexible Prüfung Ihrer Produkte

- Durchgängige Transparenz über Anlage, Änderungen und Freigabe der Prüfaufträge

- Automatisierte Prüfschritterstellung auf Basis Ihrer Produktionsdaten, z. B. im Reinigungszustand der Maschine

- Reduzierung von Zeitaufwänden durch Wegfall händischer Protokolle

- Reduzierung potenzieller Fehlerquellen durch Wegfall von Übertragungsfehlern

Modul Qualitätssicherung (QS)

Standard

- Verwaltung von Prüfplänen

- Live-Trigger aus MDE/BDE

- Automatische Erstellung von Prüfaufträgen

- Digitale Checklisten und Formulare

- Anbindung von Peripheriegeräten

- Proaktives Informationsmanagement

- Stichproben (SPC)

Modul Produktionsplanung (PP)

Standard

- Stammdatenverwaltung

- Artikelverwaltung

- Arbeitspläne und Stücklisten

- Fertigungsvarianten und -versionen

- Gantt-Chart mit Drag & Drop-Funktion

- Szenarien und Auswertungen

Zusatzfunktionen

- Bedarfshandling

- Digitale Plantafel

- Vorplanung

- Planungsgruppen

- Rüstregeln

- Personalverfügbarkeitsplanung

- Betriebsmittelverfügbarkeitsplanung

- Materialverfügbarkeitsplanung

- Semaphoren

- Joins

- Halbautomatische Planung

- Vollautomatische Planung

Modul Traceability (TRC)

Standard

- Erfassung von eingesetzten Komponenten

- Erfassung von Prozesswerten

- Baugruppenverwaltung

- Prozessverriegelung

- Seriennummern und Chargenverwaltung

- Etikettendruck

- Auswertungen zur Rückverfolgbarkeit

- Verwaltung von Produktionslägern

Modul Instandhaltung (INST)

Standard

- Ressourcenverwaltung

- Verwaltung von Instandhaltungsplänen

- Automatische Erstellung von Instandhaltungsaufträgen

- Digitale Formulare

- Proaktives Informationsmanagement

- Personaleinsatz- und Bedarfsplanung

- Alarmierungen

- Anfragen- und Aufgabenverwaltung

- MTBF/MTTR

- Autonome Instandhaltung

Modul Maschinendatenerfassung (MDE)

Standard

- Erfassung von Maschinenzuständen, Leistung und Qualität

- Komfortable Auswertungen

- Ausschussdifferenzierung

- Leistungsauswertung

- MTBF/MTTR

- Rüstzeitauswertung

- Zustandsauswertung

- Overall Equipment Effectiveness

(OEE) - Ressourcenlogbuch

Zusatzfunktionen

- KPI-Konfigurator

- Prozessdatenerfassung

- Prozessmeldungen

- Datenarchivierung

- Rüstregeln

Modul Betriebsdatenerfassung (BDE)

Standard

- Fertigungsauftragsmanagement

- Arbeitspläne

- Stücklisten

- Auftragsarten

- Erfassung von Mengen und Zeiten

Zusatzfunktionen

- Personalzeiterfassung

- Rezepturverwaltung (DNC/EDS)

- Dokumentenanzeige

- ERP-Buchungen

- Automatischer Auftragsstart

- Betriebsmittel-Datenerfassung

Basis-Modul

Standard

- Audit Trail

- Basis-/Stammdatenverwaltung

- Benutzer-/Rechteverwaltung

- Mehrsprachigkeit

- Report Designer

- Template Designer

Zusatzfunktionen

- Testsystem

- Alarmierungen

- OPC UA Server

- ERP-Schnittstelle

- Cloud/BI-Connector

- Online-Monitoring

- Maschinenanbindung

- Klassifizierungen

- Mobile Client

- View Client

- Office Client

Fair und flexibel – Sie erwerben nur, was Sie benötigen

Unsere sieben Module werden durch Zusatzfunktionen und viele Funktionalitäten ergänzt. Dadurch haben Sie die Möglichkeit, die Software-Bausteine auszuwählen, welche Sie benötigen und können die Digitalisierung Ihrer Fertigung Schritt für Schritt ausbauen. Wir beraten Sie gerne!

Handschriftliche Prüfung in der Produktion

Automatisiert/FASTEC 4 PRO

Modul Qualitätssicherung (QS): Im Detail

Der Weg zur papierlosen Fabrik ist vielerorts noch weit – ein Mix aus händisch auszufüllenden Excel-Tabellen und Word-Dokumenten ist immer noch die gelebte Praxis. Und das gilt für zahlreiche Produktionsbetriebe – unabhängig von Branche und Größe. Zudem müssen Maschinenbediener selbst für die Einhaltung der Prüfintervalle sorgen sowie Entscheidungen über die Qualität der produzierten Ware treffen („in Ordnung“/„nicht in Ordnung“). Abgesehen vom Ressourceneinsatz und dem Zeitaufwand begleitet also ständiges Fehlerpotential die Datenerhebung – von der Einhaltung der Prüfintervalle über die präzise Protokollierung bis hin zur Auswertung.

FASTEC bietet eine attraktive Antwort auf die vorgenannte komplexe Thematik: Papierlos, präzise und hochkonfigurierbar sind die wesentlichen Attribute des neu entwickelten Qualitätsmoduls. In Kombination mit dem Modul Betriebsdatenerfassung (BDE) öffnet es die Tür zur digitalen Auftragsdokumentation. Einem ganzheitlichen und durchgängigen Ansatz folgend bietet das neue Modul bereits in seiner ersten Version deutlich mehr Funktionen als viele gängige SPC-Tools.

Während es bei SPC vornehmlich um die manuelle Erfassung von variablen und attributiven Merkmalen geht, bietet das Modul Qualität eine Reihe weiterer Funktionen an, wie zum Beispiel die Digitalisierung von Rüstchecklisten.

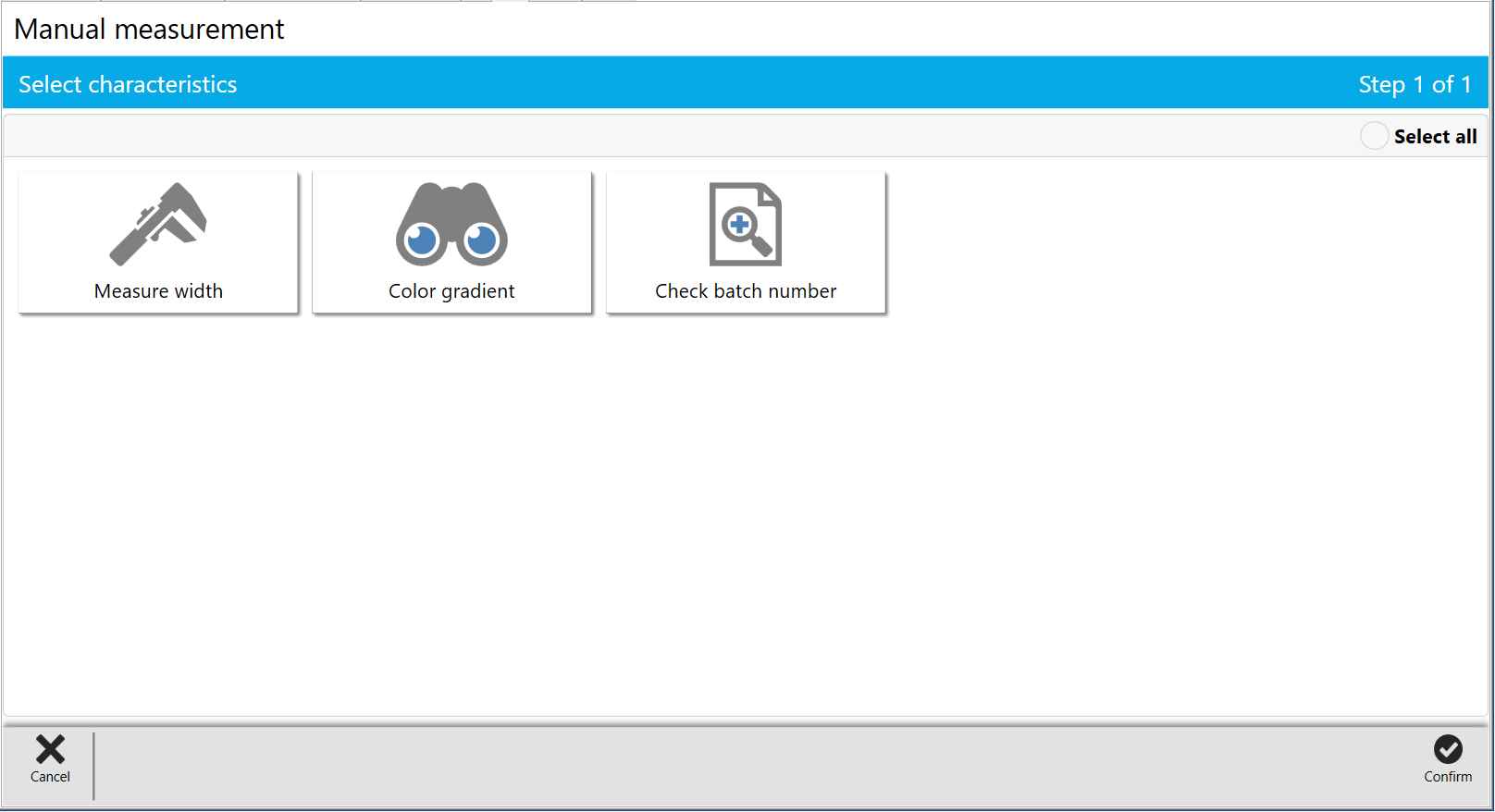

Nach selbst festgelegten Intervallen können verschiedene, in einem Prüfplan festgelegte Merkmale kontrolliert werden. Darüber hinaus können Prozess- und Qualitätsprüfungen zum Teil automatisiert und ohne Maschinenbediener erfolgen. Dies ist beispielsweise bei der Kontrolle der Lot-Codes mittels stationärem Scanner möglich.

Das Spektrum der möglichen Prüfpunkterzeugung lässt keine Wünsche offen: Automatisierte Trigger für die digitale Kontrolle, zum Beispiel von Zeit, Arbeitsgang, Menge und Zustand, sichern durchgängige Qualitätskontrollen und bringen noch mehr Transparenz in die Produktion. In Kombination mit der Erstellung individueller Prüfpläne zur Festlegung von Schrittfolgen, variablen, attributiven und komparativen Merkmalen sowie umfangreichen Möglichkeiten zur Text- und Zahleneingabe verkürzt das Modul den Weg zur papierlosen Fabrik spürbar und gewinnbringend.

Erfahren Sie mehr über unsere Module und Referenzlösungen!

In unserem Download-Bereich erhalten Sie Einblicke in Referenzlösungen unserer Kunden sowie weiterführende Detailinformationen zu unseren Modulen und Software-Lösungen. Lassen Sie sich inspirieren!

Haben Sie Interesse an individuellen Lösungen für Ihr Unternehmen?

Mit uns profitieren Sie von umfangreicher Projekterfahrung in der digitalen Fertigung verschiedener Branchen. Bei über 400 Kunden. Weltweit. Seit 1995.

Haben Sie Interesse an individuellen Lösungen für Ihr Unternehmen?

Mit uns profitieren Sie von umfangreicher Projekterfahrung in der digitalen Fertigung verschiedener Branchen. Bei über 400 Kunden. Weltweit. Seit 1995.

Für wen wir arbeiten

Vom Automobilzulieferer über Lebensmittelproduzenten, Pharmaunternehmen bis hin zum Spielwarenhersteller, vom hochspezialisierten Nischenanbieter, über den ambitionierten Mittelständler bis hin zum international aufgestellten Großkonzern – über 400 Kunden rund um den Globus setzen auf Software for Production – made in Paderborn. Darunter auch: